Want to help the environment? Start small and use technology, according to Patagonia Inc.

The retailer recently overhauled the way it processes paper hang tags. Paper hang tags are still attached to each piece of clothing and include information about the brand and product. But Jennifer Patrick, global manager of packaging and branding, found a way to use QR codes and reduce paper hang tag versions from 453 to 20. That’s 170,000 pounds less landfill waste generated in a single season.

There are other advantages, too. The cost of assigning hang tag projects, designing, writing, managing, and fixing problems all adds up, Patrick says.

“We’re looking at money. We’re looking at environment. But we’re also analyzing the impact on our internal resources,” she says.

Between 2018 and 2022, Patagonia had a total of 453 paper hang tag versions it used for its spring and fall collections.

The outdoor clothing retailer has been in business since 1973 and continues to evolve how it offsets its impact on the environment. Patrick has been in the print industry for more than 20 years. She says she understands that internal process changes take time and need research. But the payoff to both retailers and the environment is worthwhile.

“We found that we didn’t lose any customer communication like product features or material technologies by eliminating the [paper] inserts,” she says.

Communicate with customers

Nearly one-fourth (24%) of U.S. consumers say they’ll avoid companies whose actions contradict their values, according to research company Forrester Inc.’s March 2021 global trust imperative survey. 20% said they’d prefer competitors over the offending company. 19% would stop doing business with the company temporarily. 19% would buy fewer products/services from the company. And 16% would warn friends and family to avoid the company completely.

Patagonia’s hang tag change was small but important, Patrick says.

“Patagonia is not Adidas or Nike,” she says. “This change is a small impact overall, but was a big impact for us.”

Patagonia ranks No. 205 in Digital Commerce 360’s database of the Top 1000 online retailers.

Patagonia uses technology to redirect customers

Packaging is set early on in the lifecycle of a piece of clothing, Patrick says. Before the change, editorial and design teams created content for each tag. Patagonia then printed the 453 tag designs and sent them to the factory floor. Once purchase orders came in, the tags were then attached and ready to go. With approximately 1,000 different clothing styles, it took too much time to ensure the right tags were on each style of clothing, she says.

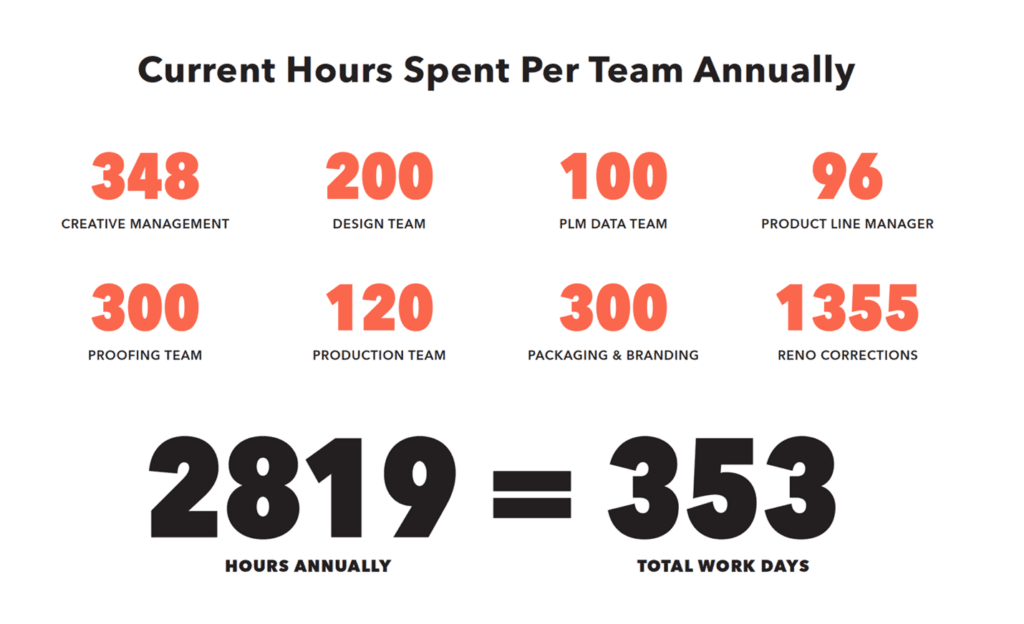

Patrick created a time study and found that the new QR code inserts cut work time from 353 days to three days annually.

“It took 353 days, almost a year’s worth of our time spent on this process throughout the company,” Patrick says.

Before switching to digital QR codes, Patagonia spent approximately 2,819 hours per year on garment hang tag production.

Retailers should challenge designers to use more technology and less materials, Patrick says.

“If retailers go more digital with information, it opens up the opportunity to save on materials — that saves us money.”

Think outside the box. Use technology to reduce single-use materials, she says.

“Use less and it’s not just a win from an environmental standpoint; it’s a financial win,” Patrick says.

Stay on top of the latest developments in the ecommerce industry. Sign up for a complimentary subscription to Digital Commerce 360 Retail News.